CELLULAR CONCRETE

Technologies and Applications of Cellular Concrete

From machinery, additives, and expertise comes Isoltech technology. Discover our applications and patents.

Low-Density Cellular Concrete for High-Insulating Solutions

Our Low-Density technology enables the production of cellular concrete with densities ranging from 100 to 200 kg per cubic meter, providing exceptional insulating properties. This feature, combined with the simplicity of the production process, allows for the rapid, efficient, and economical creation of thermally insulated sandwich panels for civil and industrial applications. It is also ideal for frame panels with insulating cores and for filling bricks and blocks.

The fluidity of the material in Low-Density technology, which is easily workable in all its applications, facilitates quick and compact installation. Thanks to these properties, low-density cellular concrete presents itself as a versatile and efficient solution, optimal for meeting various insulation needs.

Isocem S/X: Eco-Friendly Cellular Concrete - Patent Based on Recycling Aggregates

Our High Tech Isocem S/X technology is an innovative patent that involves the use of waste or secondary raw materials derived from silica-based processing residues, recovery materials, or recycled waste as a replacement for sand.

This approach creates a virtuous cycle that promotes sustainability in the construction sector by transforming waste into valuable resources for the production of eco-friendly cellular concrete.

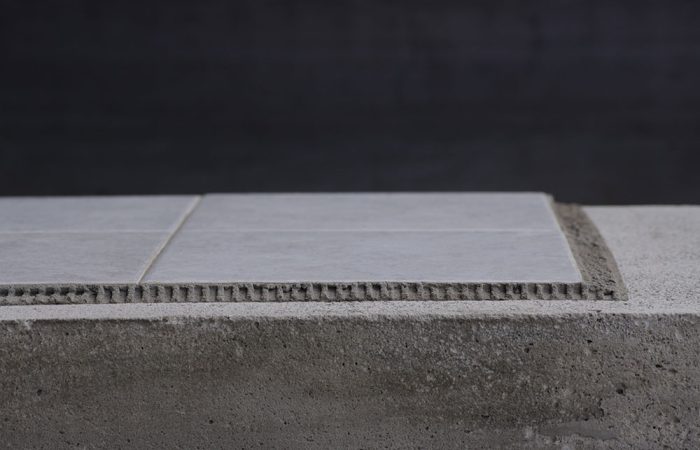

Increment D 1300 - Single-Layer Cellular Concrete Screed with Medium Density

The Increment D 1300 technology represents an innovation in the field of single-layer substrates, allowing for the creation of stronger, lighter screeds with enhanced acoustic and thermal insulation properties. Increment D 1300 can be applied using an IBS 15 machine or a mobile plant such as Fluocem.

Fluoplan - Fluid Composite Screed in Sand and Cement

Fluoplan is an innovative technology, developed and patented by Isoltech, for the production of fluid screeds in sand and non-premixed cement. Unlike cellular concrete, Fluoplan is an excellent heat conductor as it contains no air.

With a specific weight ranging from 2100 to 2200 kg per cubic meter, Fluoplan offers numerous advantages: it is easily pumpable, self-leveling without settling, and does not crack. This advanced technology ensures uniform and durable screeds, ideal for various construction applications. Fluoplan meets the demands of a market increasingly oriented towards global solutions, which include the supply of composite screed, incorporating Fluoplan, and cellular concrete made with Isocem S/L foaming agent and Increment L water reducer.

At Isoltech, we believe in continuous innovation for a more sustainable future. For over 40 years, our commitment to the cellular concrete sector has allowed us to anticipate trends with cutting-edge solutions that meet market demands.