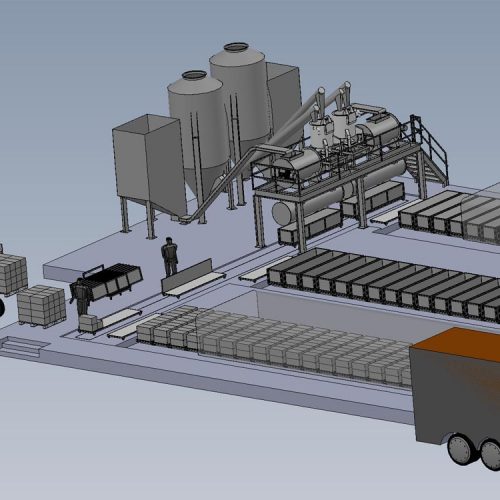

AUTOMATIC PLANT FOR THE PRODUCTION OF CELLULAR CONCRETE BLOCKS

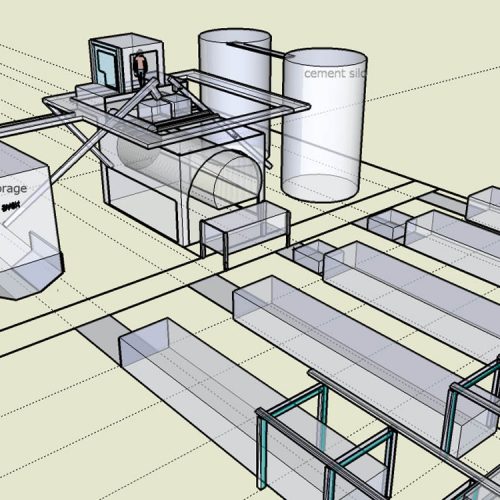

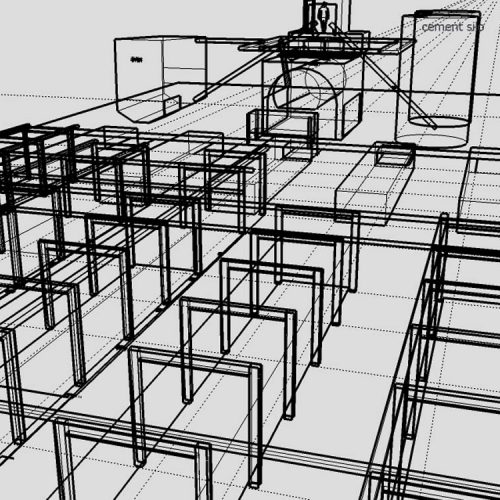

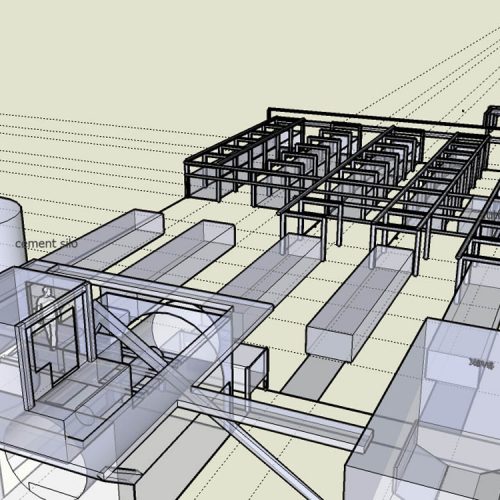

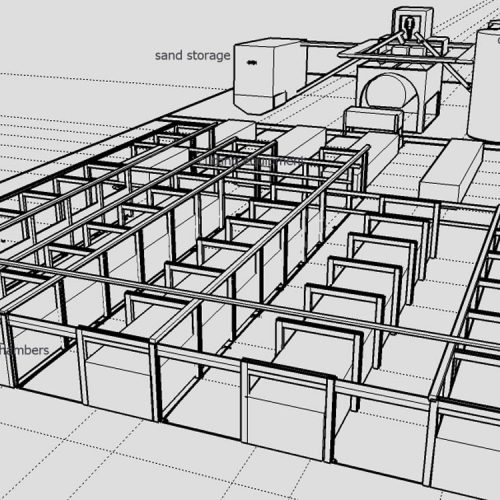

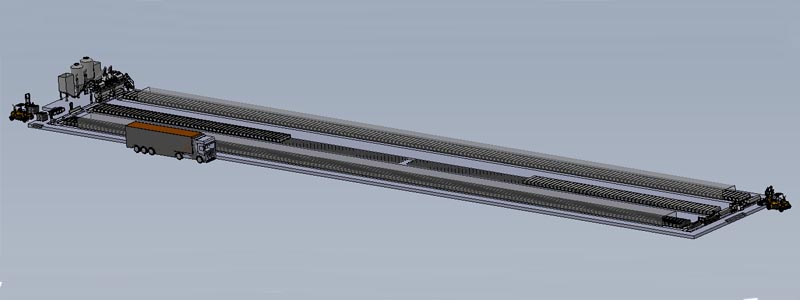

The automatic plant for the production of cellular concrete uses the most sophisticated version of the IBS-08 automatic machine, an automatic cutter with formworks on wheels without dividing knives that run along the circuit of the various production stages:

- filling of the formworks with cellular concrete

- curing of cellular concrete blocks produced

- cutting of the cellular concrete blocks into the desired sizes

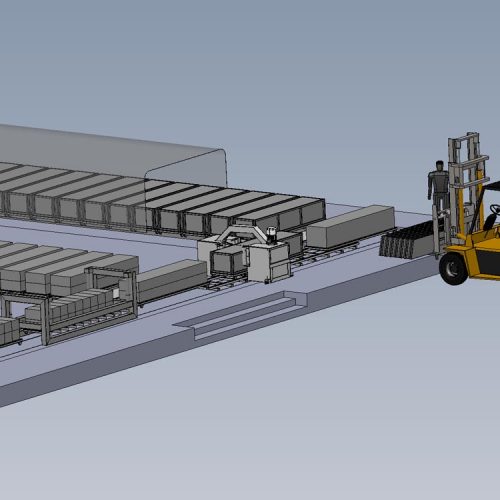

- palletising of the blocks for distribution/sale

The IBS-08 machine is configured to obtain the maximum yield of a plant ideal for significant production for expanding markets.

The formworks – after being filled with cellular concrete – circulate on the rail towards the cutter which, independently, picks up the open formwork for the cutting of the material into individual blocks of the programmed thickness, and then places it back on the circuit for the curing phase and subsequent packaging.

The automatic plant for the production of cellular concrete blocks is set up by our technicians at the customer’s site and tested alongside the personnel in charge of managing the system.

Our turnkey service not only includes the set-up of the plant, but also the identification of the correct mix design of the material and the subsequent production of cellular concrete blocks.

PHOTO GALLERY AUTOMATIC PLANT FOR THE PRODUCTION OF CELLULAR CONCRETE BLOCKS

CONTACT US TO RECEIVE MORE INFORMATION

CONTACT US TO RECEIVE MORE INFORMATION