The semi-automatic plant for cellular concrete block production uses the IBS-08 automatic machine and a series of molds that vary depending on the plant configuration.

The IBS-08 machine is configured to dose and mix components, ensuring consistent quality of the produced material.

The IBS-08 machine utilizes cement silos and a screw conveyor, along with a hopper and conveyor belt for selected sand, which can be provided by the customer or supplied directly by Isoltech upon request.

Each day, the molds are manually opened, and after a quick cleaning, they are refilled. The material hardens overnight, taking advantage of the spontaneous heat generated by hydration, without the need for energy consumption.

This process ensures efficient and sustainable production of cellular concrete blocks.

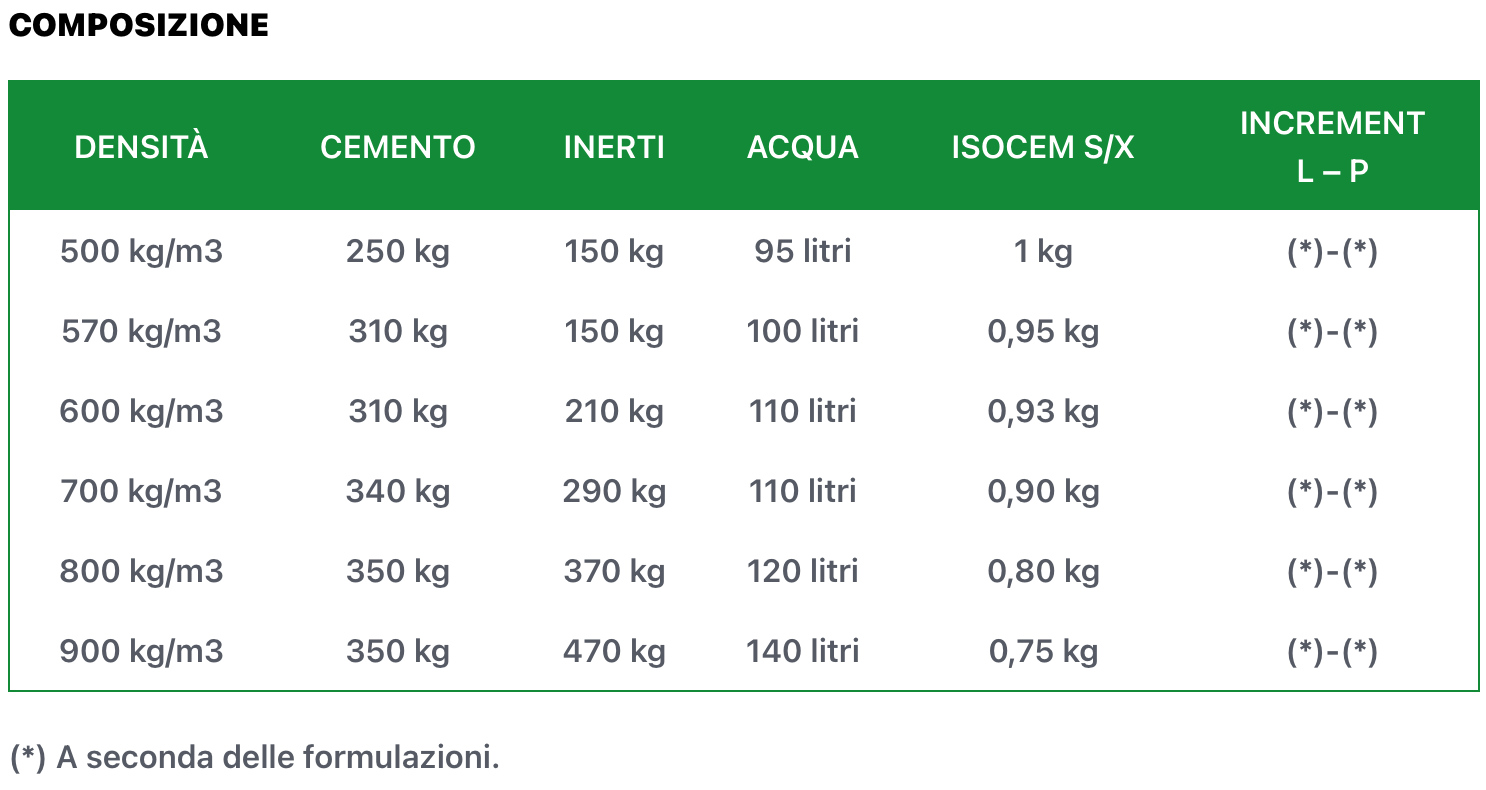

Our technical team commissions the plant at the customer’s site, tests it together with the operating personnel, and delivers the expected spare parts kit. Thanks to the turnkey service, the testing includes identifying the material composition and producing the cellular concrete blocks.

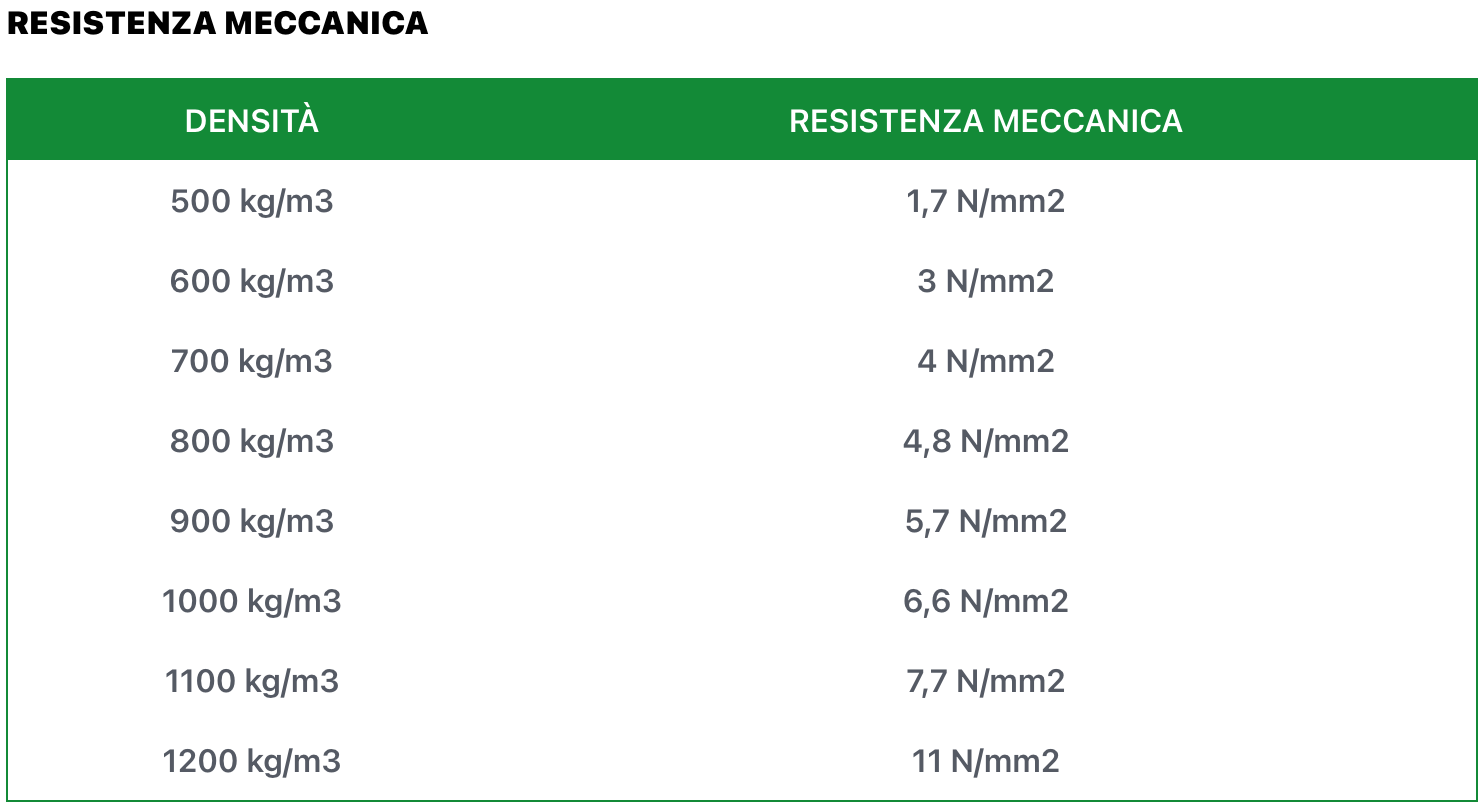

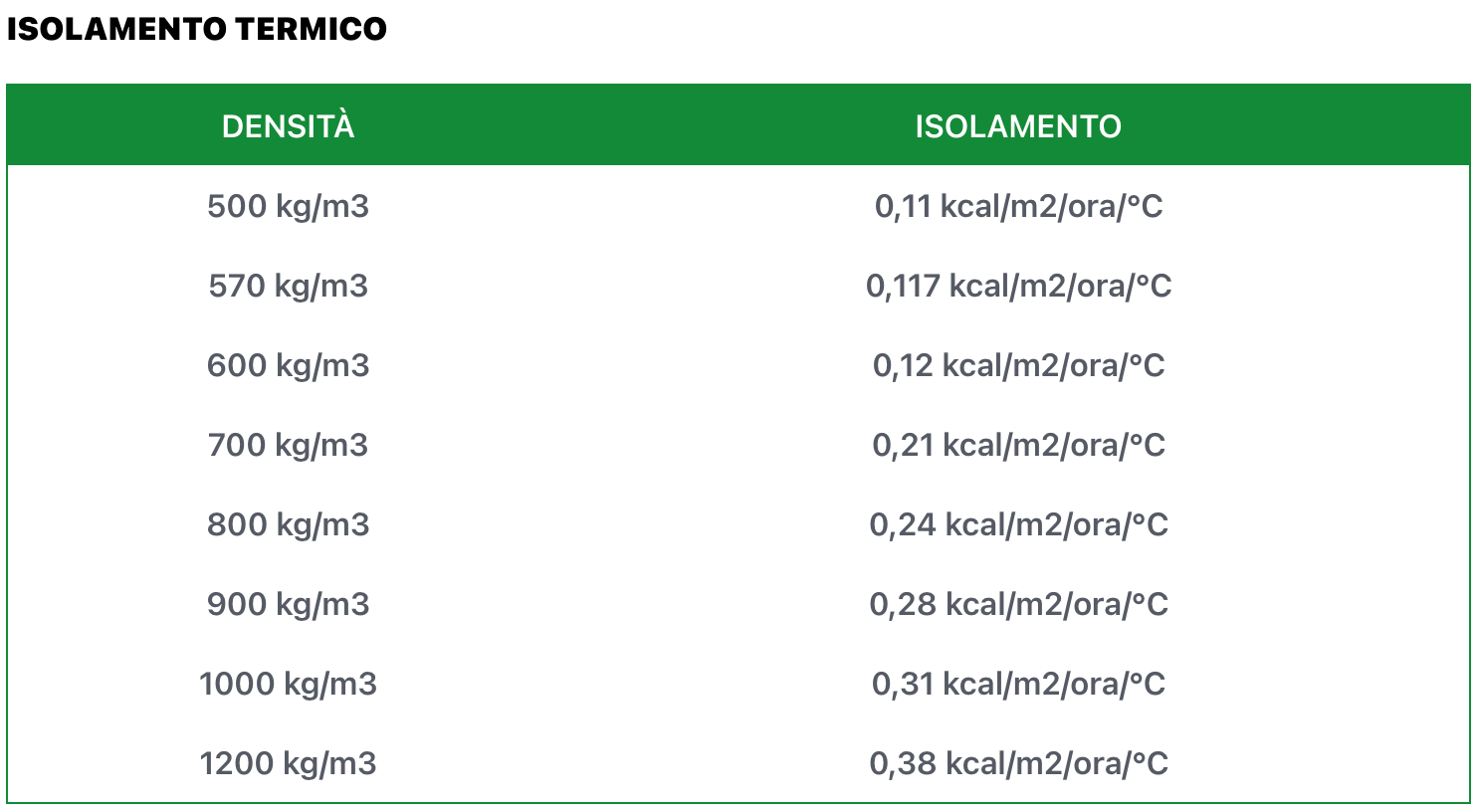

Isocem S/X conferisce le migliori resistenze, specialmente iniziali, agli impasti di cemento cellulare a media densità:

Company specialized in solutions for cellular concrete production.

Via Amburgo 2 24040

Verdellino (BG) – Italia

Tel (+39) 035 4820680

Fax (+39) 035 4820680

info@isoltech.it

© 2024 ISOLTECH Srl – C.F./P.Iva 01800190165